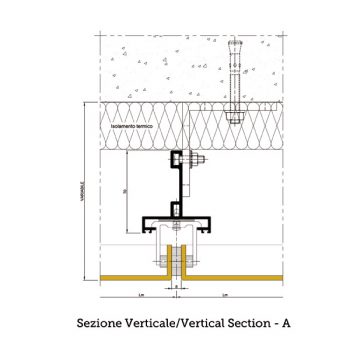

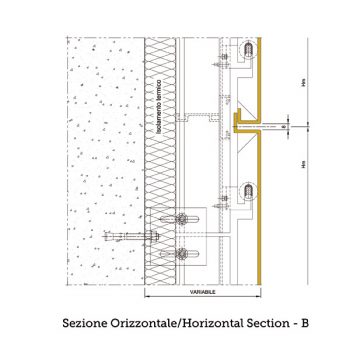

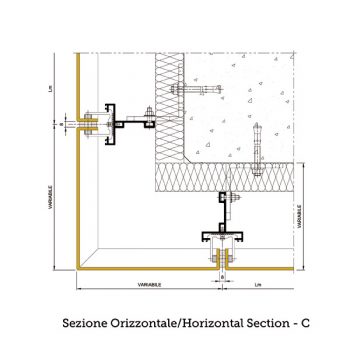

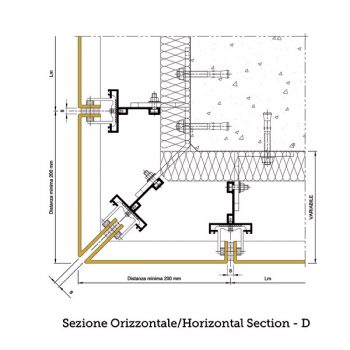

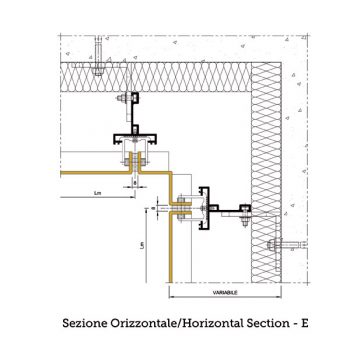

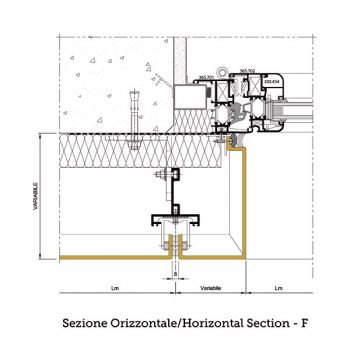

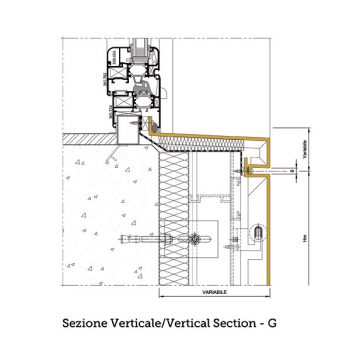

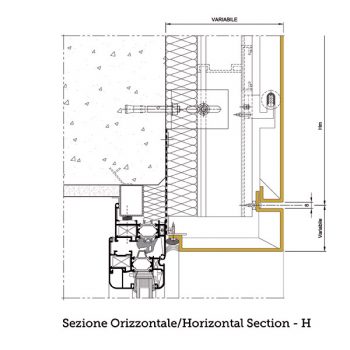

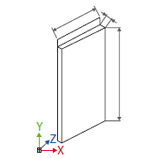

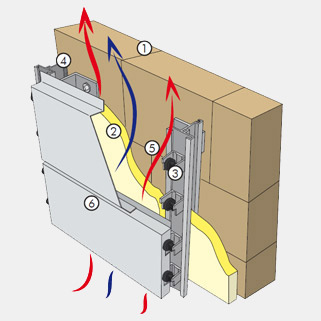

1 – Masonry wall 2 – Coat insulation 3 – Substructure upright 4 – Fixing bracket 5 – Invisible fixing system 6 – Solid aluminum b_ox cladding

Facciate

Ventilated Façade b_ox

B_Ox System, with 1,2 to 3,0 mm pure aluminium panels, is a green and susteinable alternative to classic aluminium sandwich panels with synthetic cores. By its nature aluminium is not flame spreading and it is resistant to shocks.

With B_Ox System we can provide the full set of our anodized, powder coated or sublimated finishes, with infinite range of colors and many textures, able to satisfy the most demanding architectural design.

Finishing is applied after shaping/cutting pieces, with unrival level of quality compared to standard composite panels.Full set of substructure system is available to arrange cladding solutions easily.

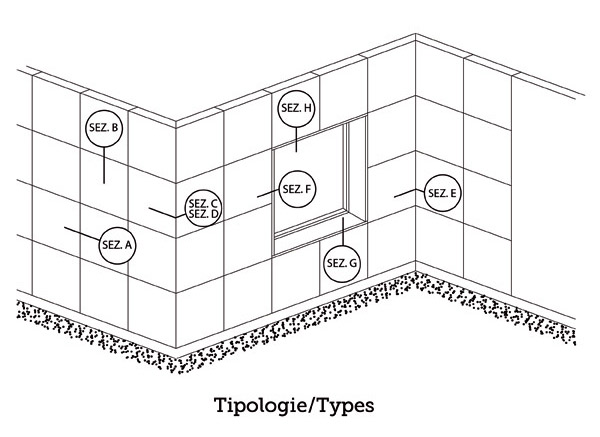

TYPES / LAYING

BENEFITS

PROCESSING

TREATMENTS

Surface Finishes

English

English Italiano

Italiano